|

|

Machine Automation Controllers

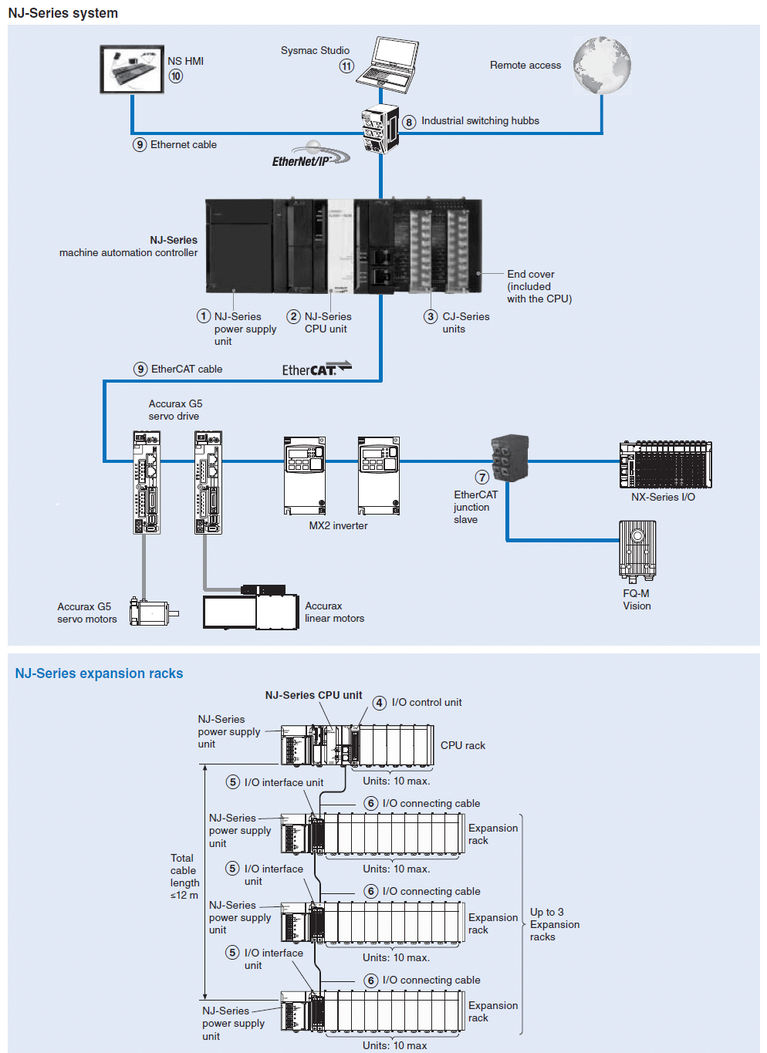

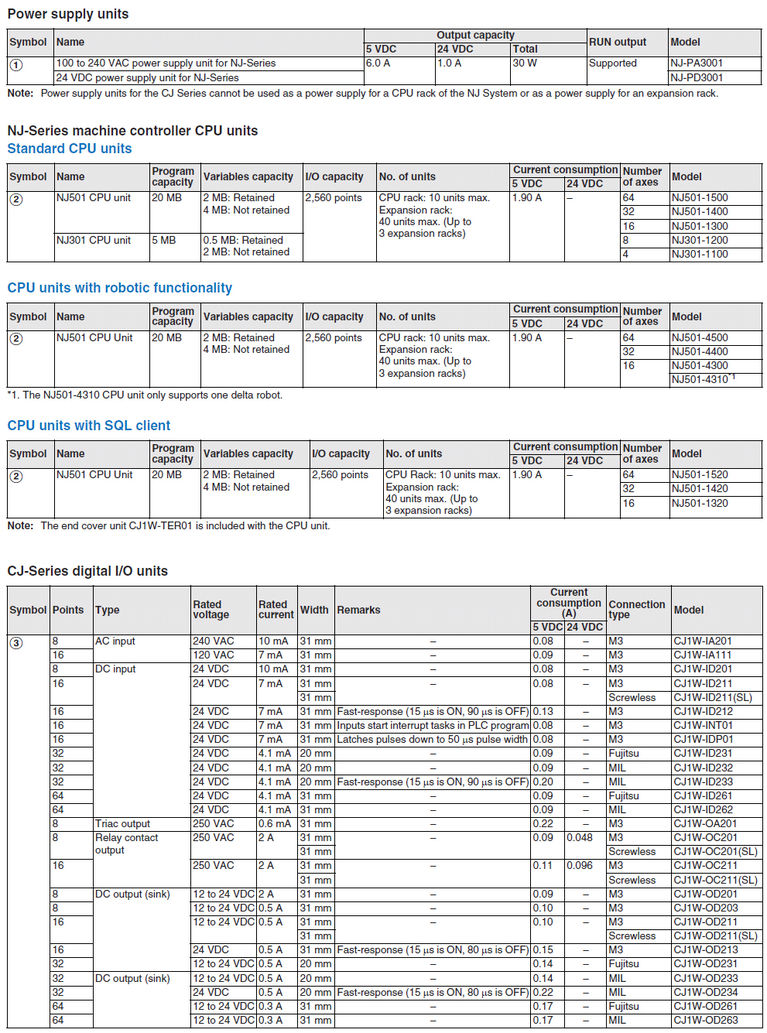

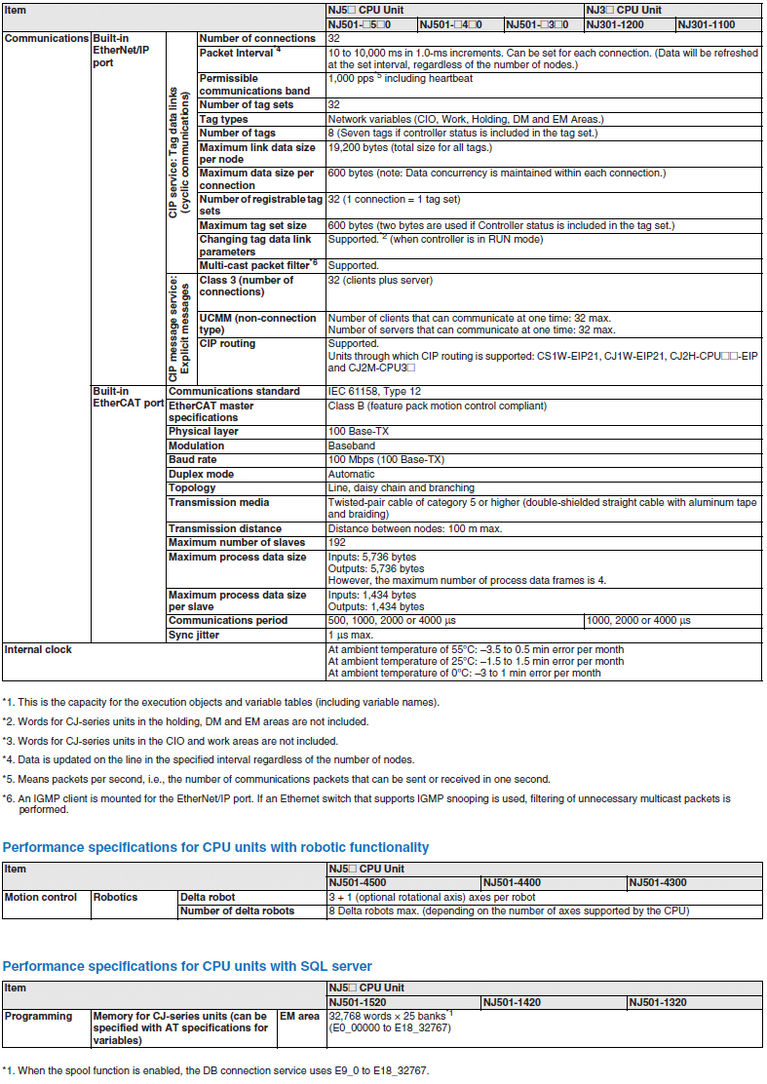

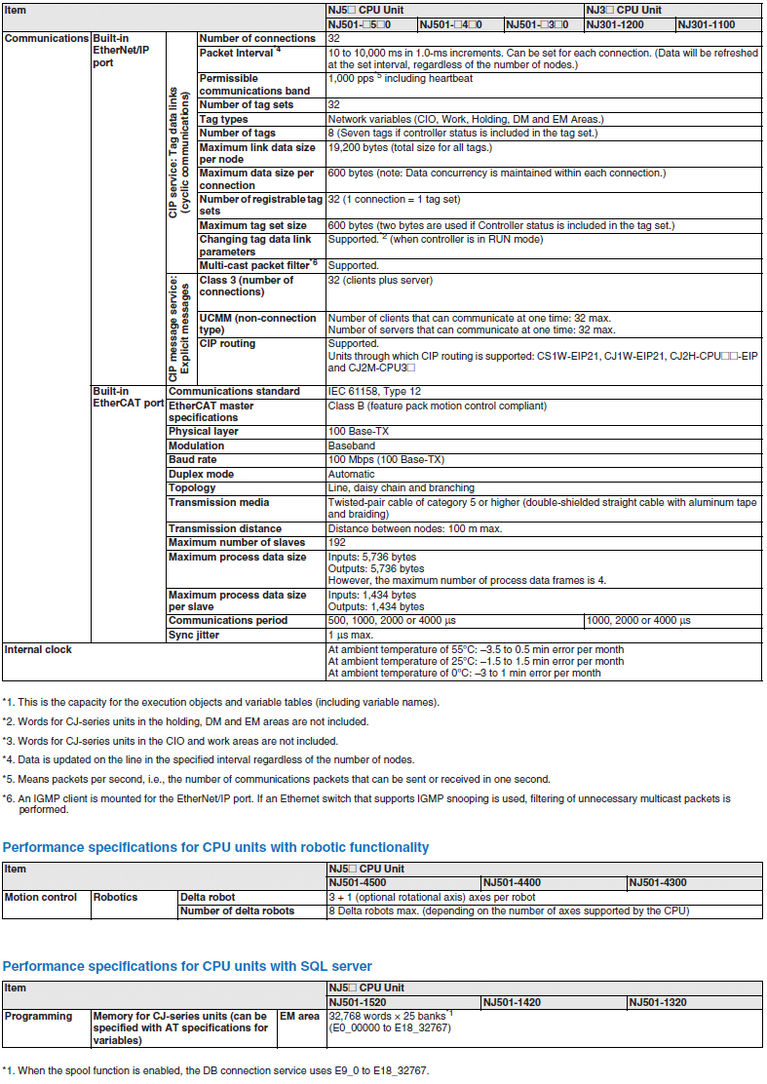

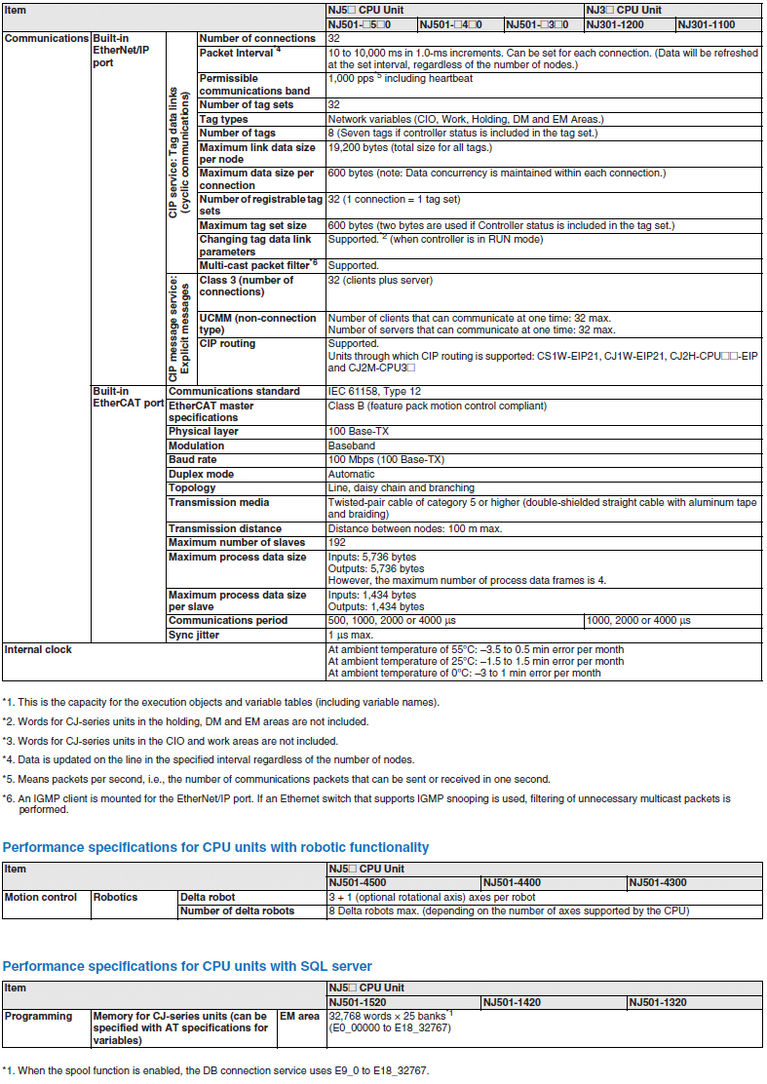

The NJ Series controller incorporates an Intel processor proven for harsh industrial environments with fan-free operation and runs under RTOS, a real time operating system. It is scalable with a choice of 4, 8, 16, 32 and 64 axis CPUs. A cycle time of less than 500 µs can be achieved for applications of up to 32 axes. The NJ Series is a Machine Controller for Sequence and Motion functionality and offers CPU units with Robotics function and SQL Client.

View items...

The Sysmac automation platform integrates the safety solution within our one connection and one software concept. One connection is realised through the use of Safety over EtherCAT - FSoE - protocol. The one software is achieved by using the Sysmac Studio for configuration, programming and maintenance. The NX safety system consists of safety controller and safety I/O units.

View items...

Sysmac Studio provides an integrated development environment to set up, program, debug, and maintain NJ-series Controllers and all other Sysmac devices, as well as EtherCAT slaves.

View items...

Complete and robust machine automation

The heart of the new automation platform is the Sysmac NJ 5 machine automation controller. A completely redesigned hardware system with a powerful Intel® Atom™ processor proven for harsh environments shifts from a rigid ASIC based architecture to an adaptable and scalable software centric design. This ultra-compact market leading technology gives you ultimate flexibility without compromising on the traditional reliability and robustness that you have come to expect from Omron PLC's.

Real-Time OS

The NJ-series hardware has been designed to adapt to the quickly changing demands of a machine automation controller. A typical system built around an application specific integrated circuit can be difficult to change and enhance. The NJ series uses the proven Intel® Atom™ processor to allow real-time improvements to the cores of the system. This adaptability virtually guarantees a future-proof system that can lead today's automation technology and trends.

Key Features:

• Advanced motion features

• CPU performance

• Quick response to customer needs

• Unique application solutions

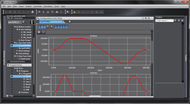

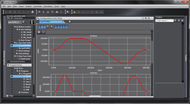

Accurate and Precise

Because Omron developed every aspect of the control core, run-time is predictable and reliable with no instability caused from third party code. With this advantage, NJ-series functions can be accurately and precisely predicted for real world operation. Features such as CAM profile simulations that provide not only position data, but additionally velocity, acceleration and jerk give a detailed prediction of how the machine motion will actually perform. Only Omron can deliver such a stable and efficient controller, ensuring your application will behave as desired.

|

Key Features:

• Logic simulation

• Motion simulation

• Stable operation and reliability

• Quick and predictable start-up time |

Motion and Logic in ONE

With a powerful processor comes multiple systems integrated into one controller. Providing advanced motion control with proven machine logic in one unit gives your machine the ultimate advantage. The NJ-series seamlessly combines two prominent application requirements to reduce hardware and development cost. Handshaking and other intermediate steps needed with multiple systems that create overhead, inefficiency and delay are eliminated while functionality and performance are increased. Sequence control, motion control, and I/O refreshing are all executed in the same control period. This enables precise sequence and motion control in a fixed period with minimal deviation.

Key Features:

• Increased control

• Comprehensive motion and logic function set

• One program for motion and logic

Advanced Hardware Design

Building on Omron's reputation for quality and innovation, the NJ-series is designed to be a solid performer in the class of machine automation controllers. Fan-less operation with efficient heat dissipation eliminates mechanical failure and extends the life of the system. Ports such as Ethernet and USB provide a standard interface for connection and communication. An SD memory card slot integrated in the CPU provides a common media for data storage. Backwards compatibility is provided with most CJ type IO units for easy upgrade and a full range of available and existing unit types.

Key Features:

• Class leading compact size

• Front facing connections for efficient panel design

• Standard feature Ethernet/IP port

• Standard feature EtherCAT Master port

Proven Technology

Developed from years of experience, the NJ-series combines the newest technology with the stability and performance of yesterday's PLC's. Built upon the knowledge and success of previous controllers, the NJ-series advances with improvements such as task scheduling, error processing, synchronized control and multitasking. The NJ-series system provides the hardware reliability that you expect from a PLC with the flexibility and power of a machine automation controller.

Industry Standards and Global Conformance

Standard IEC 61131-3 based programming languages are supported and motion control instructions that are based on PLCopen standards and an Instruction set (POU's) that follow IEC rules are provided. Hardware compliance with EMC and EC directives ensure your system will operate according to widely accepted regulations. Global standards conformance combined with Omron's extensive worldwide support network allows your machine to comply with a variety of international markets without limitations.

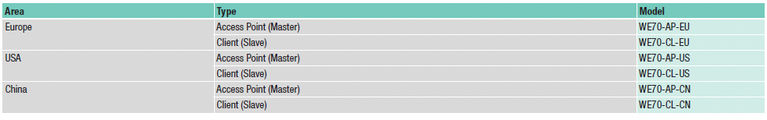

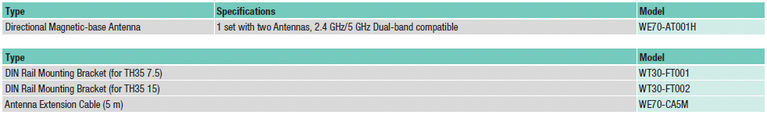

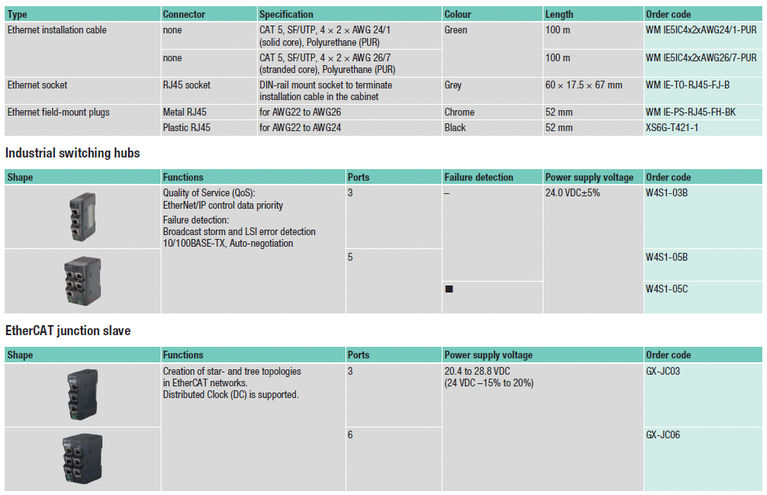

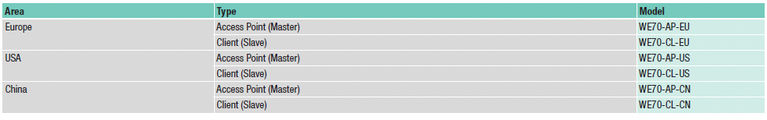

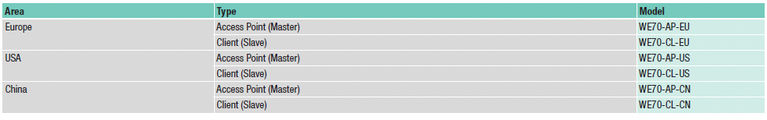

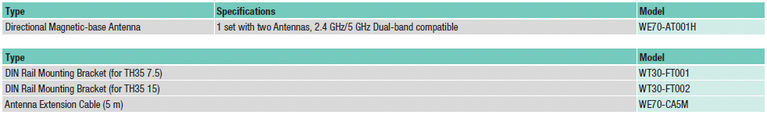

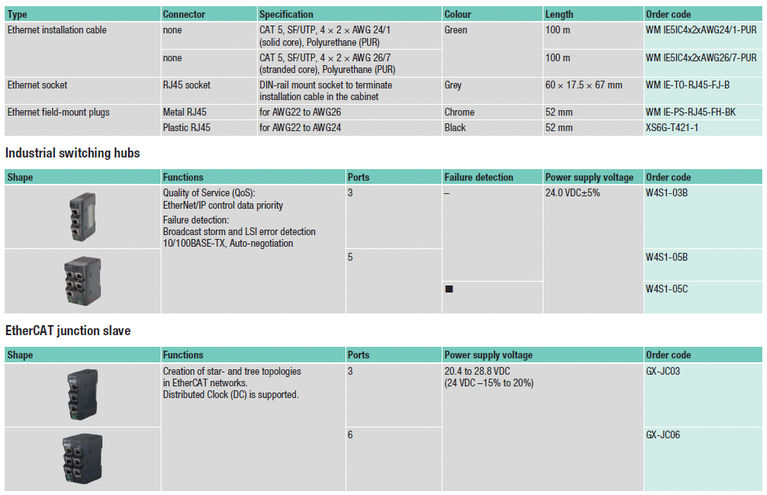

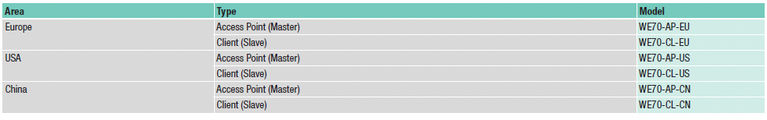

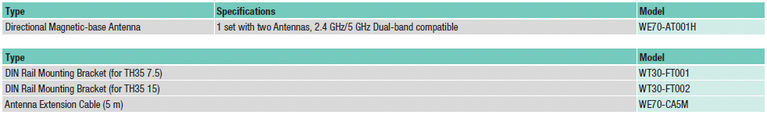

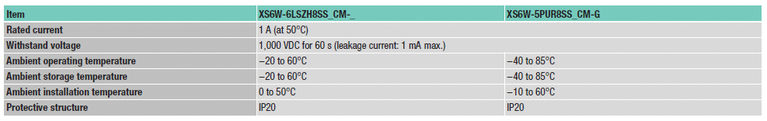

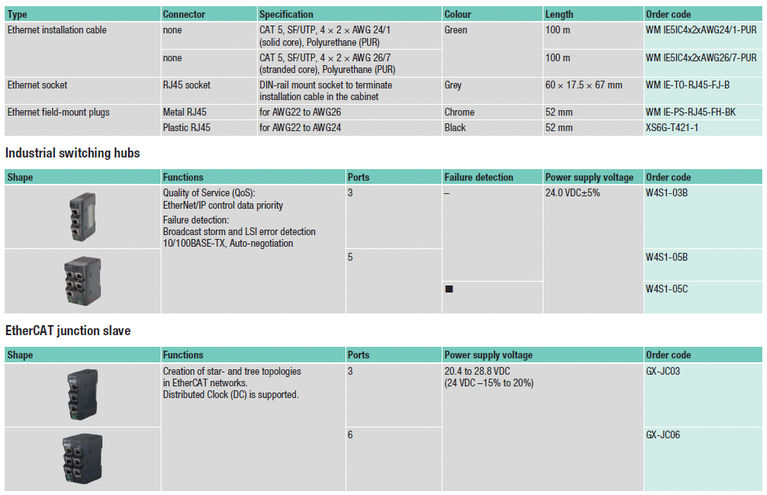

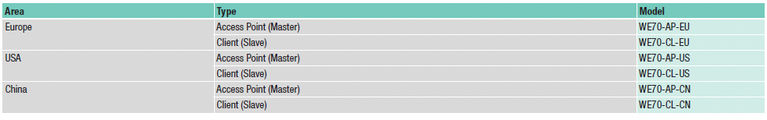

Wireless LAN units

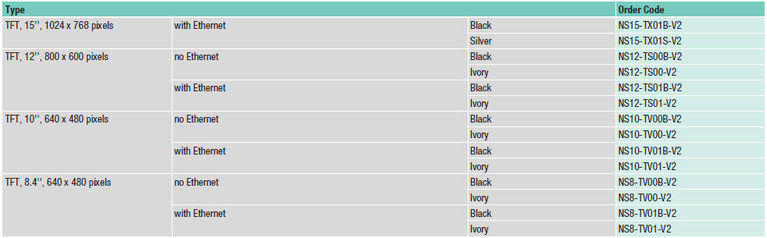

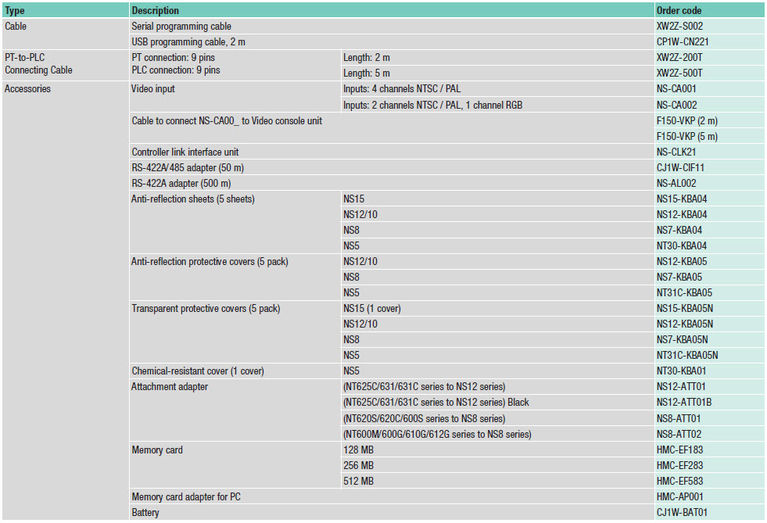

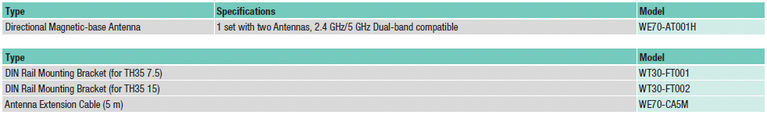

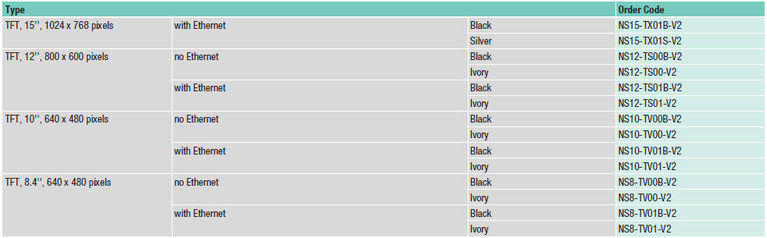

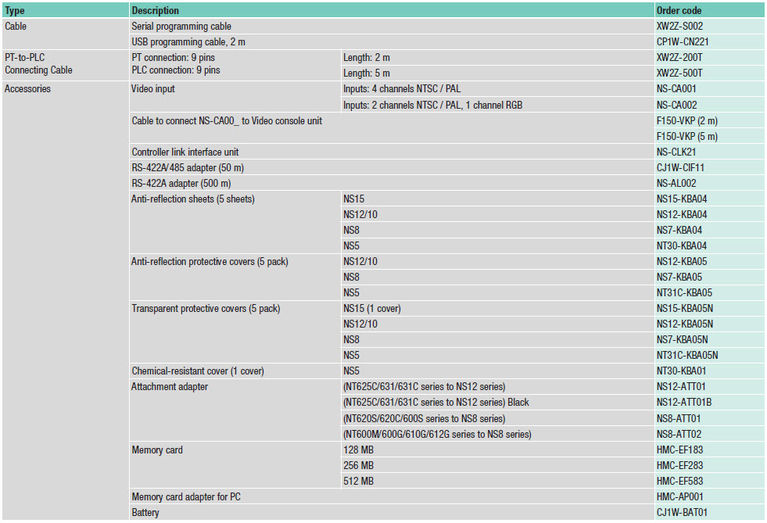

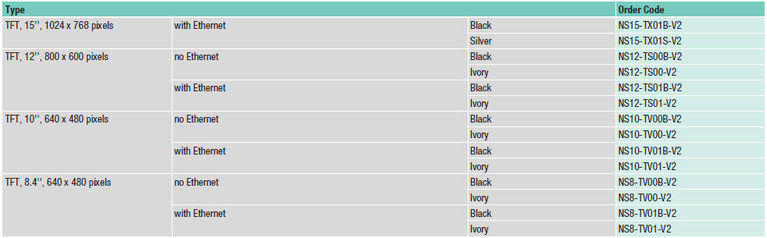

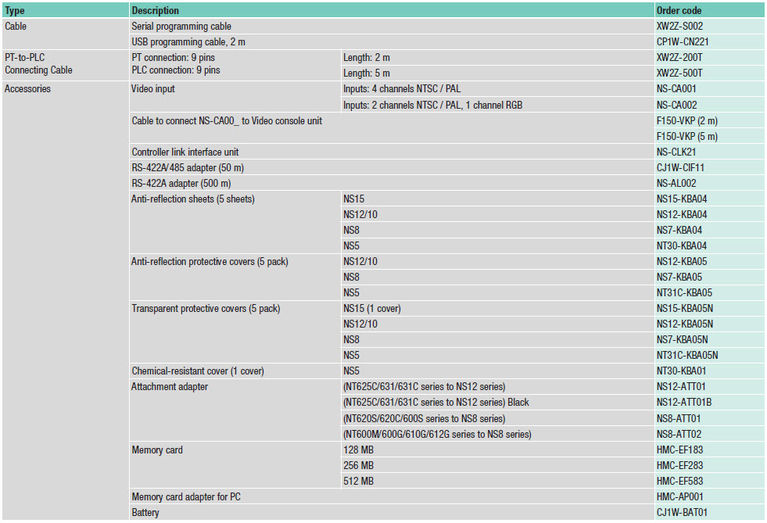

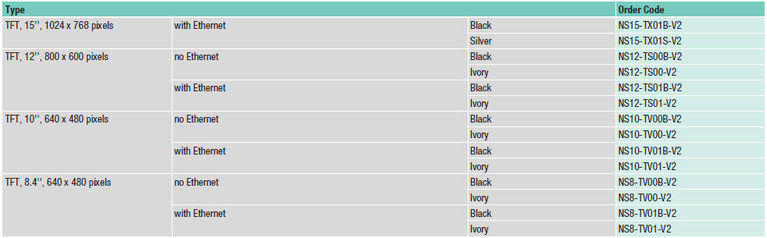

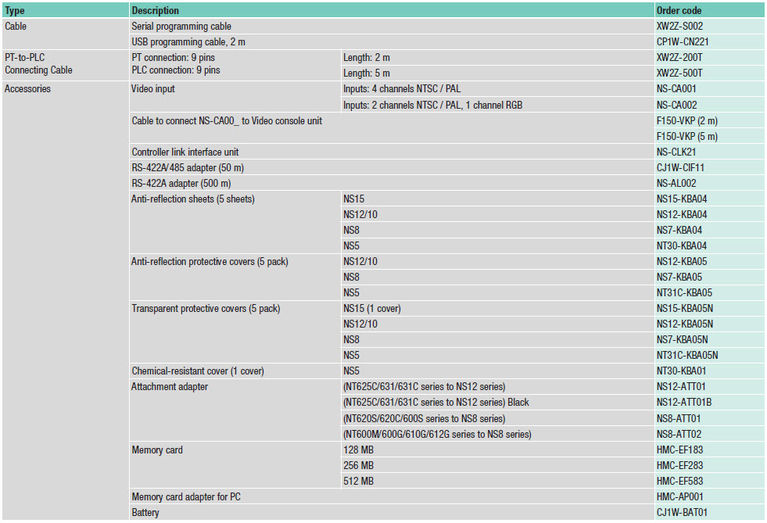

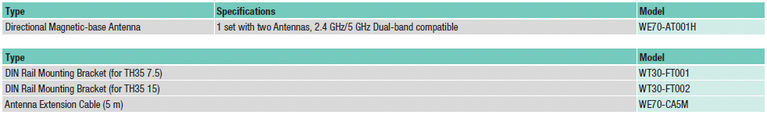

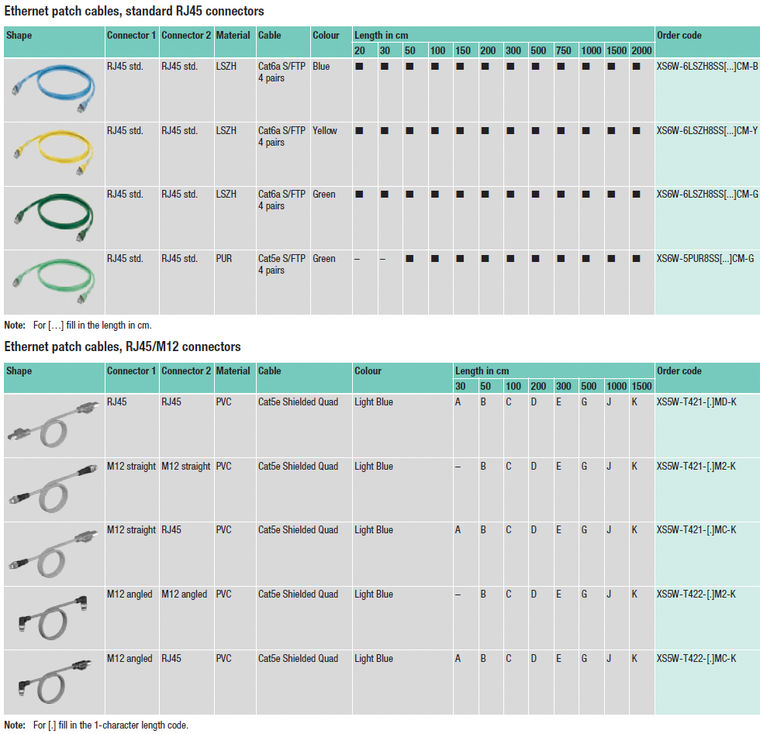

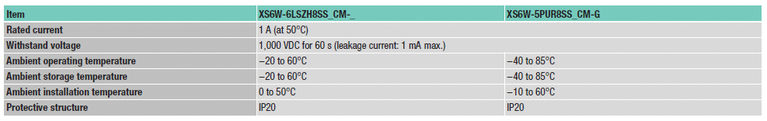

NS HMI Series

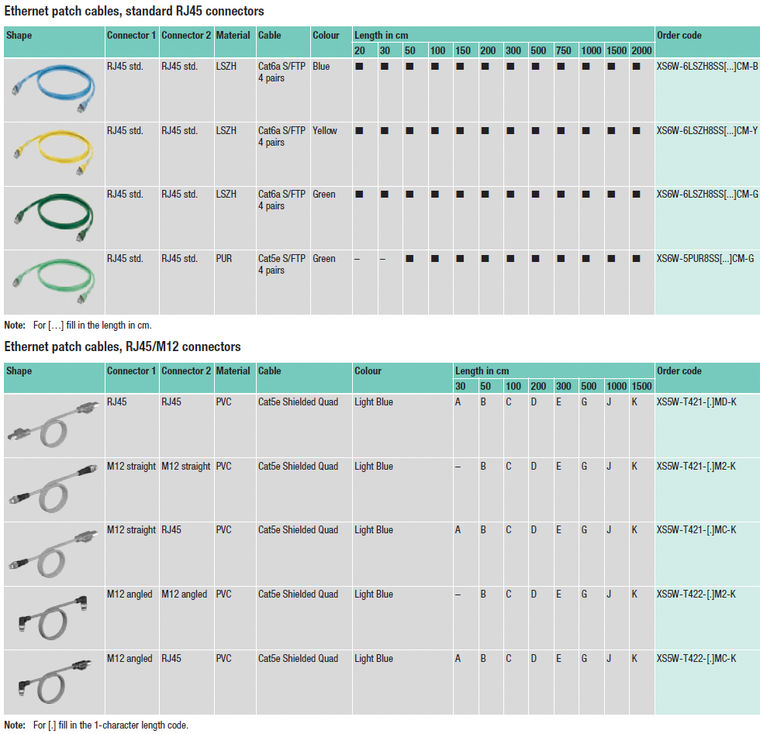

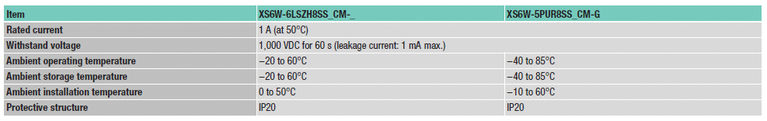

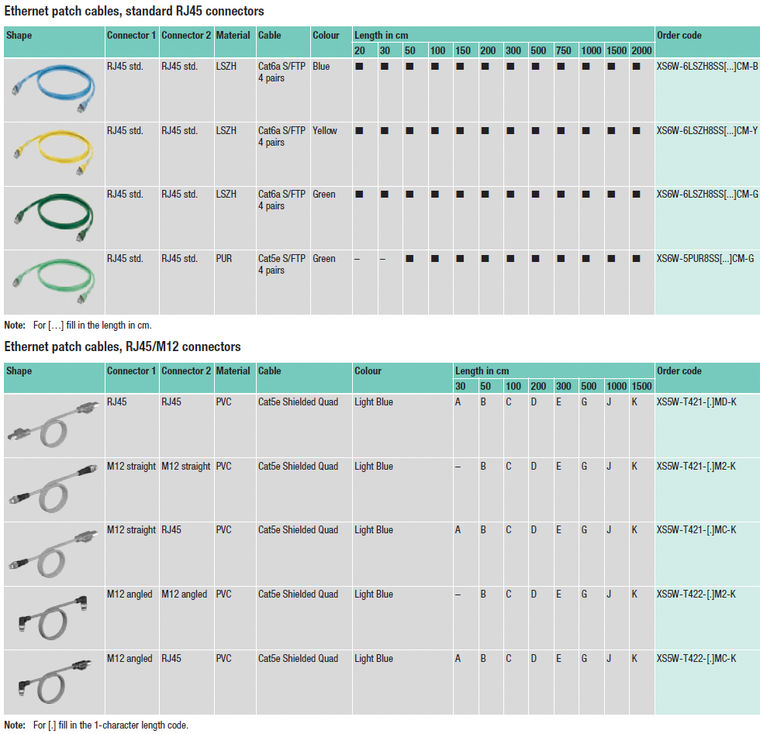

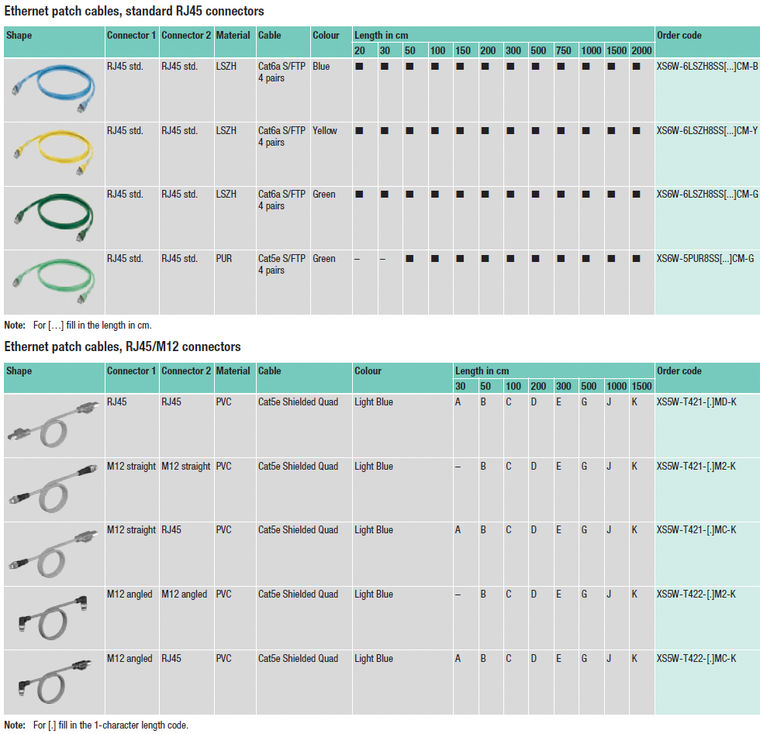

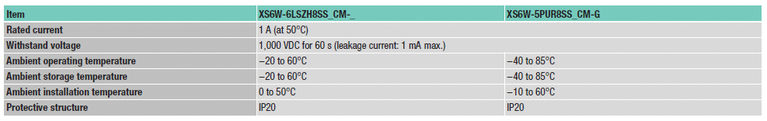

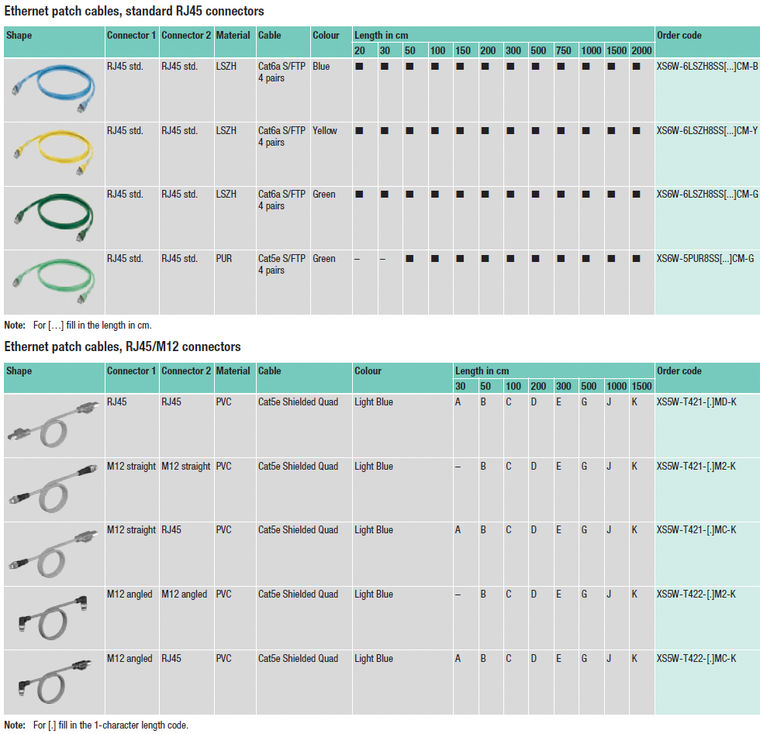

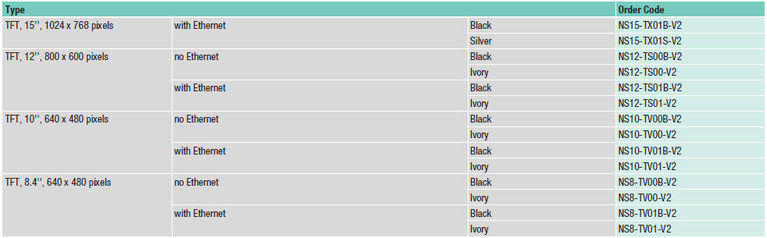

EtherNET Cables

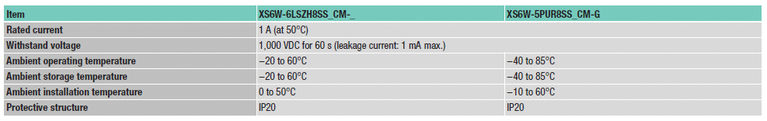

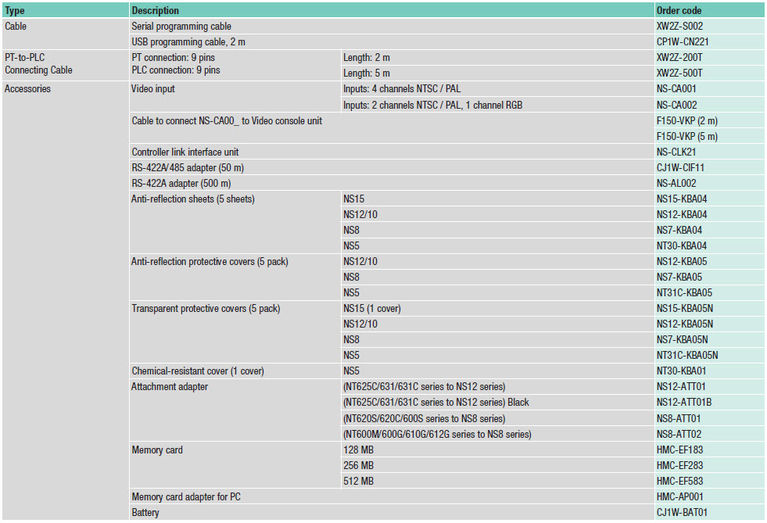

EtherNET accessories

Sysmac StudioCreated to give you complete control over your automation system, Sysmac Studio integrates configuration, programming and monitoring in a simple interface.

NJ machine controller with integrated Robotic functions

The NJ Robotics controller is the core of the system architecture which uses the EtherCAT bus to provide the highest motion performance for demanding packaging applications.

The controller is able to control up to 8 robots by providing independent or synchronized movements with the others motion devices installed in the machine, such as single servo axis or group of axes.

The integration of the NJ-Robotics controller with the G5 servo systems allows you to achieve the maximum throughput in your Pick & Place applications by taking all the advantages provided by and the kinematics structure of the Delta robots.

The synchronization with multiple conveyors can be realized very easily by using specific commands which have been specially developed to optimize the cycle time of the Pick & Place applications that use Delta robots.

Robotics functions

In addition to the standard NJ functions, the Robotics CPU provides a set of specific function blocks to control multiple delta robots machine. The system allows to define the kinematics parameters to control any kind of Delta-3 robot, with or without rotational axis, and you can even create dedicated user coordinate systems to simplify the programming. The performance of the Pick & Place trajectories and any related synchronization with the conveyors can be optimized thanks to smart time-based motion commands developed specifically to match the widest through-put needs.

Key features:

• Integrated Delta Robot control

• Control of up to 8 Delta robots in 2 ms/ 4 Delta robots in 1 ms

• Conveyor tracking function

• Automatic workspace check

Real-Time OS

The NJ-series hardware has been designed to adapt to the quickly changing demands of a machine automation controller. A typical system built around an application specific integrated circuit can be difficult to change and enhance. The NJ series uses the proven Intel® Atom™ processor to allow real-time improvements to the cores of the system. This adaptability virtually guarantees a future-proof system that can lead today's automation technology and trends.

Key Features:

• Advanced motion features

• CPU performance

• Quick response to customer needs

• Unique application solutions

Accurate and Precise

Because Omron developed every aspect of the control core, run-time is predictable and reliable with no instability caused from third party code. With this advantage, NJ-series functions can be accurately and precisely predicted for real world operation. Features such as CAM profile simulations that provide not only position data, but additionally velocity, acceleration and jerk give a detailed prediction of how the machine motion will actually perform. Only Omron can deliver such a stable and efficient controller, ensuring your application will behave as desired.

|

Key Features:

• Logic simulation

• Motion simulation

• Stable operation and reliability

• Quick and predictable start-up time |

Motion and Logic in ONE

With a powerful processor comes multiple systems integrated into one controller. Providing advanced motion control with proven machine logic in one unit gives your machine the ultimate advantage. The NJ-series seamlessly combines two prominent application requirements to reduce hardware and development cost. Handshaking and other intermediate steps needed with multiple systems that create overhead, inefficiency and delay are eliminated while functionality and performance are increased. Sequence control, motion control, and I/O refreshing are all executed in the same control period. This enables precise sequence and motion control in a fixed period with minimal deviation.

Key Features:

• Increased control

• Comprehensive motion and logic function set

• One program for motion and logic

Advanced Hardware Design

Building on Omron's reputation for quality and innovation, the NJ-series is designed to be a solid performer in the class of machine automation controllers. Fan-less operation with efficient heat dissipation eliminates mechanical failure and extends the life of the system. Ports such as Ethernet and USB provide a standard interface for connection and communication. An SD memory card slot integrated in the CPU provides a common media for data storage. Backwards compatibility is provided with most CJ type IO units for easy upgrade and a full range of available and existing unit types.

Key Features:

• Class leading compact size

• Front facing connections for efficient panel design

• Standard feature Ethernet/IP port

• Standard feature EtherCAT Master port

Proven Technology

Developed from years of experience, the NJ-series combines the newest technology with the stability and performance of yesterday's PLC's. Built upon the knowledge and success of previous controllers, the NJ-series advances with improvements such as task scheduling, error processing, synchronized control and multitasking. The NJ-series system provides the hardware reliability that you expect from a PLC with the flexibility and power of a machine automation controller.

Industry Standards and Global Conformance

Standard IEC 61131-3 based programming languages are supported and motion control instructions that are based on PLCopen standards and an Instruction set (POU's) that follow IEC rules are provided. Hardware compliance with EMC and EC directives ensure your system will operate according to widely accepted regulations. Global standards conformance combined with Omron's extensive worldwide support network allows your machine to comply with a variety of international markets without limitations.

Wireless LAN units

NS HMI Series

EtherNET Cables

EtherNET accessories

Sysmac StudioCreated to give you complete control over your automation system, Sysmac Studio integrates configuration, programming and monitoring in a simple interface.

NJ machine controller with SQL Client functionality

The DB Connection function allows the NJ Machine Controller to directly access SQL Database on a server connected to the built-in EtherNet/IP port by executing DB instructions

• DB Connection services to insert, update, select to/from relational database

• Oracle Database of Oracle Corporation and SQL Server of Microsoft Corporation are supported

• No additional software, hardware or Server Middleware is required

• A single NJ-series CPU Unit can access up to three databases on up to three servers

• Log File of special instructions and processing into SD Card

• Fail-Safe design against information exchange error or power interruption: data can be spool into non volatile memory

Real-Time OS

The NJ-series hardware has been designed to adapt to the quickly changing demands of a machine automation controller. A typical system built around an application specific integrated circuit can be difficult to change and enhance. The NJ series uses the proven Intel® Atom™ processor to allow real-time improvements to the cores of the system. This adaptability virtually guarantees a future-proof system that can lead today's automation technology and trends.

Key Features:

• Advanced motion features

• CPU performance

• Quick response to customer needs

• Unique application solutions

Accurate and Precise

Because Omron developed every aspect of the control core, run-time is predictable and reliable with no instability caused from third party code. With this advantage, NJ-series functions can be accurately and precisely predicted for real world operation. Features such as CAM profile simulations that provide not only position data, but additionally velocity, acceleration and jerk give a detailed prediction of how the machine motion will actually perform. Only Omron can deliver such a stable and efficient controller, ensuring your application will behave as desired.

|

Key Features:

• Logic simulation

• Motion simulation

• Stable operation and reliability

• Quick and predictable start-up time |

Motion and Logic in ONE

With a powerful processor comes multiple systems integrated into one controller. Providing advanced motion control with proven machine logic in one unit gives your machine the ultimate advantage. The NJ-series seamlessly combines two prominent application requirements to reduce hardware and development cost. Handshaking and other intermediate steps needed with multiple systems that create overhead, inefficiency and delay are eliminated while functionality and performance are increased. Sequence control, motion control, and I/O refreshing are all executed in the same control period. This enables precise sequence and motion control in a fixed period with minimal deviation.

Key Features:

• Increased control

• Comprehensive motion and logic function set

• One program for motion and logic

Advanced Hardware Design

Building on Omron's reputation for quality and innovation, the NJ-series is designed to be a solid performer in the class of machine automation controllers. Fan-less operation with efficient heat dissipation eliminates mechanical failure and extends the life of the system. Ports such as Ethernet and USB provide a standard interface for connection and communication. An SD memory card slot integrated in the CPU provides a common media for data storage. Backwards compatibility is provided with most CJ type IO units for easy upgrade and a full range of available and existing unit types.

Key Features:

• Class leading compact size

• Front facing connections for efficient panel design

• Standard feature Ethernet/IP port

• Standard feature EtherCAT Master port

Proven Technology

Developed from years of experience, the NJ-series combines the newest technology with the stability and performance of yesterday's PLC's. Built upon the knowledge and success of previous controllers, the NJ-series advances with improvements such as task scheduling, error processing, synchronized control and multitasking. The NJ-series system provides the hardware reliability that you expect from a PLC with the flexibility and power of a machine automation controller.

Industry Standards and Global Conformance

Standard IEC 61131-3 based programming languages are supported and motion control instructions that are based on PLCopen standards and an Instruction set (POU's) that follow IEC rules are provided. Hardware compliance with EMC and EC directives ensure your system will operate according to widely accepted regulations. Global standards conformance combined with Omron's extensive worldwide support network allows your machine to comply with a variety of international markets without limitations.

Wireless LAN units

NS HMI Series

EtherNET Cables

EtherNET accessories

Sysmac StudioCreated to give you complete control over your automation system, Sysmac Studio integrates configuration, programming and monitoring in a simple interface.

NJ machine controller with SQL Client functionality

The DB Connection function allows the NJ Machine Controller to directly access SQL Database on a server connected to the built-in EtherNet/IP port by executing DB instructions

• DB Connection services to insert, update, select to/from relational database

• Oracle Database of Oracle Corporation and SQL Server of Microsoft Corporation are supported

• No additional software, hardware or Server Middleware is required

• A single NJ-series CPU Unit can access up to three databases on up to three servers

• Log File of special instructions and processing into SD Card

• Fail-Safe design against information exchange error or power interruption: data can be spool into non volatile memory

Real-Time OS

The NJ-series hardware has been designed to adapt to the quickly changing demands of a machine automation controller. A typical system built around an application specific integrated circuit can be difficult to change and enhance. The NJ series uses the proven Intel® Atom™ processor to allow real-time improvements to the cores of the system. This adaptability virtually guarantees a future-proof system that can lead today's automation technology and trends.

Key Features:

• Advanced motion features

• CPU performance

• Quick response to customer needs

• Unique application solutions

Accurate and Precise

Because Omron developed every aspect of the control core, run-time is predictable and reliable with no instability caused from third party code. With this advantage, NJ-series functions can be accurately and precisely predicted for real world operation. Features such as CAM profile simulations that provide not only position data, but additionally velocity, acceleration and jerk give a detailed prediction of how the machine motion will actually perform. Only Omron can deliver such a stable and efficient controller, ensuring your application will behave as desired.

|

Key Features:

• Logic simulation

• Motion simulation

• Stable operation and reliability

• Quick and predictable start-up time |

Motion and Logic in ONE

With a powerful processor comes multiple systems integrated into one controller. Providing advanced motion control with proven machine logic in one unit gives your machine the ultimate advantage. The NJ-series seamlessly combines two prominent application requirements to reduce hardware and development cost. Handshaking and other intermediate steps needed with multiple systems that create overhead, inefficiency and delay are eliminated while functionality and performance are increased. Sequence control, motion control, and I/O refreshing are all executed in the same control period. This enables precise sequence and motion control in a fixed period with minimal deviation.

Key Features:

• Increased control

• Comprehensive motion and logic function set

• One program for motion and logic

Advanced Hardware Design

Building on Omron's reputation for quality and innovation, the NJ-series is designed to be a solid performer in the class of machine automation controllers. Fan-less operation with efficient heat dissipation eliminates mechanical failure and extends the life of the system. Ports such as Ethernet and USB provide a standard interface for connection and communication. An SD memory card slot integrated in the CPU provides a common media for data storage. Backwards compatibility is provided with most CJ type IO units for easy upgrade and a full range of available and existing unit types.

Key Features:

• Class leading compact size

• Front facing connections for efficient panel design

• Standard feature Ethernet/IP port

• Standard feature EtherCAT Master port

Proven Technology

Developed from years of experience, the NJ-series combines the newest technology with the stability and performance of yesterday's PLC's. Built upon the knowledge and success of previous controllers, the NJ-series advances with improvements such as task scheduling, error processing, synchronized control and multitasking. The NJ-series system provides the hardware reliability that you expect from a PLC with the flexibility and power of a machine automation controller.

Industry Standards and Global Conformance

Standard IEC 61131-3 based programming languages are supported and motion control instructions that are based on PLCopen standards and an Instruction set (POU's) that follow IEC rules are provided. Hardware compliance with EMC and EC directives ensure your system will operate according to widely accepted regulations. Global standards conformance combined with Omron's extensive worldwide support network allows your machine to comply with a variety of international markets without limitations.

Wireless LAN units

NS HMI Series

EtherNET Cables

EtherNET accessories

Sysmac StudioCreated to give you complete control over your automation system, Sysmac Studio integrates configuration, programming and monitoring in a simple interface.

Integrated safety into machine automation

The Sysmac automation platform integrates the safety solution within our one connection and one software concept. One connection is realised though the use of Safety over EtherCAT - FSoE - protocol. The one software is achieved by using the Sysmac Studio for configuration, programming and maintenance. The NX safety system consists of safety controller and safety I/O units. Both the safety controller and safety I/O can be freely distributed in an I/O rack throughout the network, mixing them in any combination with standard NX I/O.

• The safety controller meets Category 4, PLe according to the EN ISO 13849-1 and SIL3 according to the IEC 61508

• Up to 8 safety input points per unit

• Safety Function Blocks conforming with IEC 61131-3 standard programming

• PLCopen Function Blocks for safety

• Integration in one software, Sysmac Studio

One Machine Software

Created to give you complete control over your automation system, Sysmac Studio integrates configuration, programming and monitoring in a simple interface. This advanced tool drives the powerful new NJ-series machine automation controller giving you total control of the entire machine with one single and easy to use software. Network configuration, motion control, sequencing, machine monitoring and simulation are some of the key features integrated into the Sysmac Studio software package. One software to control and configure the entire machine with a single connection gives you the power and efficiency to develop and create like never before.

|

We have launched another attractive and multi-functional TC controller in DIN Rail format with removable socket. The E5DC with a single loop follows the outstanding control performance of the E5_C... Read more...

We have launched another attractive and multi-functional TC controller in DIN Rail format with removable socket. The E5DC with a single loop follows the outstanding control performance of the E5_C... Read more...

Omron

Omron Automation Systems

Automation Systems Machine Automation Controllers

Machine Automation Controllers Programmable Logic Controllers

Programmable Logic Controllers Compact PLC Series

Compact PLC Series Modular PLC Series

Modular PLC Series Rack PLC Series

Rack PLC Series Remote I/O

Remote I/O Modular I/O

Modular I/O Compact I/O

Compact I/O Field I/O

Field I/O Human Machine Interfaces

Human Machine Interfaces PC Based HMI

PC Based HMI HMI & Control

HMI & Control Scalable HMI

Scalable HMI Compact HMI

Compact HMI Function-key HMI

Function-key HMI Software

Software Configuration

Configuration Programming

Programming Runtime

Runtime Motion & Drives

Motion & Drives Motion Controllers

Motion Controllers PLC Based

PLC Based Stand-alone

Stand-alone Servo Based

Servo Based PC Based

PC Based Servo Systems

Servo Systems Servo Drives

Servo Drives Rotary Servo Motors

Rotary Servo Motors Linear Servo Motors

Linear Servo Motors Frequency Inverters

Frequency Inverters Basic Solution

Basic Solution Compact Solution

Compact Solution General Purpose

General Purpose Lift Applications

Lift Applications IP54 Solutions

IP54 Solutions Application software

Application software Sensing

Sensing Photoelectric Sensors

Photoelectric Sensors Fiber Optic Sensors

Fiber Optic Sensors Inductive Sensors

Inductive Sensors Limit Switches

Limit Switches Vision Sensors & Systems

Vision Sensors & Systems Measurement Sensors

Measurement Sensors Rotary Encoders

Rotary Encoders Ident Systems

Ident Systems Safety

Safety Emergency Stop Switches

Emergency Stop Switches Safety Limit Switches

Safety Limit Switches Safety Door Switches

Safety Door Switches Safety Sensors

Safety Sensors Safety Modules

Safety Modules Programmable Safety System

Programmable Safety System Safety Actuating

Safety Actuating Control Components

Control Components Temperature Controllers

Temperature Controllers Power Supplies

Power Supplies Timers

Timers Counters

Counters Programmable Relays

Programmable Relays Digital Panel Indicators

Digital Panel Indicators Photovoltaic Inverters

Photovoltaic Inverters Switching Components

Switching Components Electromechanical Relays

Electromechanical Relays Solid State Relays

Solid State Relays Monitoring Products

Monitoring Products Motion & Drives

Motion & Drives AC Inverter Drives

AC Inverter Drives Basic Solution

Basic Solution General Purpose

General Purpose Lift Applications

Lift Applications Textile

Textile Pump & Fan Solution

Pump & Fan Solution AC Servo Drives

AC Servo Drives Machine Controllers

Machine Controllers Lift Motors

Lift Motors IE4+ Drive Package

IE4+ Drive Package Mechatrolink

Mechatrolink Engineering Tools

Engineering Tools Remote I/O Modules

Remote I/O Modules ADAM-4000

ADAM-4000 Robust Remote I/O Modules

Robust Remote I/O Modules Controller Modules

Controller Modules Analog I/O Modules

Analog I/O Modules Digital I/O Modules

Digital I/O Modules ADAM-6000

ADAM-6000 Analog I/O Modules

Analog I/O Modules Digital I/O Modules

Digital I/O Modules ADAM-6100EI

ADAM-6100EI Analog I/O Modules

Analog I/O Modules Digital I/O Modules

Digital I/O Modules ADAM-6100PN

ADAM-6100PN Analog I/O Modules

Analog I/O Modules Digital I/O Modules

Digital I/O Modules ADAM-6200

ADAM-6200 Analog I/O Modules

Analog I/O Modules Digital I/O Modules

Digital I/O Modules ADAM-2000

ADAM-2000 Analog I/O Modules

Analog I/O Modules Digital I/O Modules

Digital I/O Modules Router Modules

Router Modules Gateway Modules

Gateway Modules Data Acquisition (DAQ) & Control

Data Acquisition (DAQ) & Control PCI Express Cards

PCI Express Cards PCI Cards

PCI Cards USB Modules

USB Modules PC/104 Modules

PC/104 Modules ISA Cards

ISA Cards Signal Conditioning Modules and Terminal Boards

Signal Conditioning Modules and Terminal Boards CompactPCI System

CompactPCI System PC-based Modular Industrial Controller

PC-based Modular Industrial Controller Building Automation systems

Building Automation systems Industrial Communication

Industrial Communication Embedded Automation Computers

Embedded Automation Computers Panel PC

Panel PC Automation Software

Automation Software Product Range

Product Range Soft Starter

Soft Starter